Going Full Throttle

[lead]It’s a bird! It’s a plane! It’s a plane traveling at hypersonic speed![/lead]

By David Goddard and Gina Stafford

Anyone familiar with the fictional exploits of Superman knows that part of his super powers is that he is “faster than a speeding bullet.”

Thanks to research being done in part by UT’s John Schmisseur, it will soon be possible to produce aircraft that make even the Man of Steel seem slow.

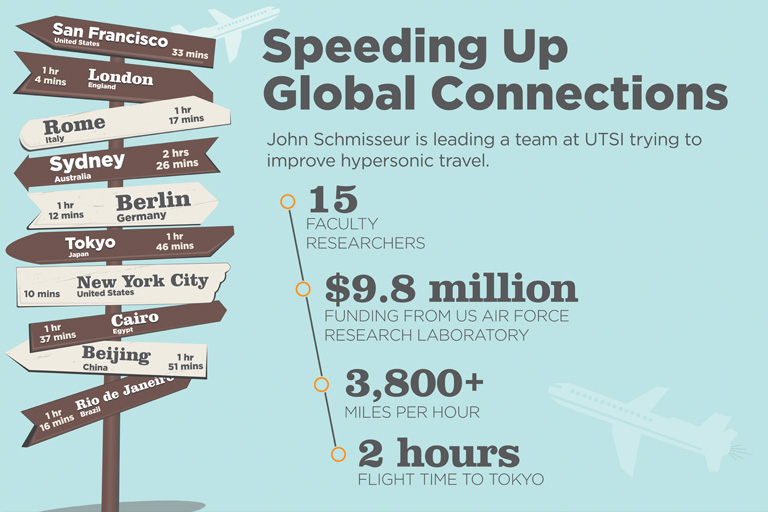

Schmisseur, the H. H. Arnold Chair in Computational Fluid Dynamics and B. H. Goethert Professor at the UT Space Institute (UTSI), is part of a team exploring the production of materials and structures for use in hypersonic aircraft travelling at more than five times the speed of sound.

At sea level, that means a speed of 3,800 miles per hour, meaning an aircraft could fly from Knoxville to Tokyo in less than two hours.

There’s just one problem.

“The heat generated by vehicles travelling that fast goes well beyond our current capabilities,” said Schmisseur. “We have to gain a better understanding of how and where that heat is most likely to build, the loads and pressures it exerts, and identify the most critical regions of the aircraft.

“The institutions in UT’s system have the competencies to help solve those riddles.”

Team Composition

The $9.8 million project, funded through the US Air Force Research Laboratory, includes Schmisseur and his colleagues at Purdue University and the University of Dayton Research Institute.

Schmisseur will be UT’s system-wide leader of the project, which will be performing both simulations and experiments to guide designs being done at Dayton. The UT team consists of 15 faculty researchers from UTSI, UT Knoxville, and UT Chattanooga.

US Senator Lamar Alexandar and US Representatives Scott DesJarlais and Chuck Fleischmann were key players in moving the project forward.

Project Goal

The team is charged with developing new materials for use in its craft that can overcome the issues created by heat at hypersonic speed.

Schmisseur has named his program the High-Speed Original Research and Innovation Zone, or HORIZON.

“Our three campuses have a lot of intellectual firepower to bring to bear on this,” said Schmisseur. “The Tennessee Department of Economic and Community Development feels that aerospace and defense are keys in the state’s economy. UT system-wide partnerships to enhance research and innovation in support of those efforts will be bolstered by this project.”

Within the next year, Schmisseur’s hope is that UTSI’s experiments will travel 15 minutes down the road to the Arnold Engineering Development Complex (AEDC), which he calls the crown jewel and epicenter of Air Force hypersonics research in the US.

What is UTSI’s main role in the project?

Schmisseur and others at UT are working to solve the issues created by extreme heat and pressure loads that are generated on the surface due to hypersonic flight.

The team will then turn over that data to Dayton, who will use it to help design the structure and material design, meaning the results UT collects will be vital to the success of the project.

AEDC operates more than 55 aerodynamic and propulsion wind tunnels, rocket and turbine engine test cells, ballistic ranges, sled tracks, centrifuges, and other specialized units, but testing takes hundreds of thousands of dollars per week, if not millions per test, according to Schmisseur.

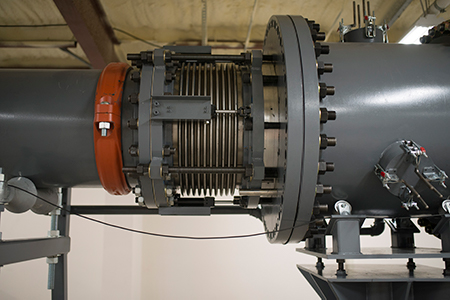

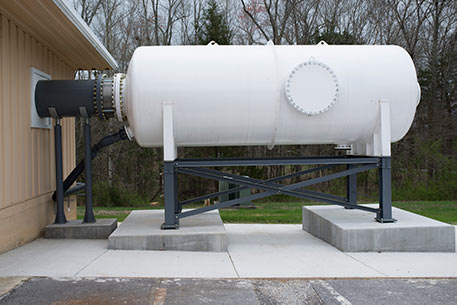

To get around that problem, he and his team have developed a massive, state-of-the-art wind tunnel facility known as the Tennessee Aerothermodynamics Laboratory, or TALon.

Schmisseur said that TALon creates “a natural pathway to a discovery, innovation, technology development and early research environment,” and that it easily helps support the mission of AEDC. It will also offer relatively low-cost experimentation at tens of dollars per test.

“We want to use hypersonic research to drive new accomplishments and growth from an industrial and economic standpoint here at home,” said Schmisseur. “Understanding how test data ultimately translates into the acquisition process will benefit manufacturing.”

Aerospace and defense sectors are already the fourth-largest economic areas for Tennessee. Improvements to those fields at UTSI could greatly benefit the state, helping its economy soar for decades to come.

Just how big is one of academia’s largest wind tunnels?

While the diameter of most supersonic wind tunnels can be measured in inches, UTSI’s will be two feet wide, 156 feet long, and housed in a nondescript metal building on campus.

During operation, a powerful vacuum is created in a large tank outside the building. The tank connects to a 105-foot tube that passes through an exterior wall, creating air flow in the wind tunnel.

Photo Gallery

UT’s John Schmisseur is leading an effort to advance hypersonic travel through his lab at UTSI, including the cutting-edge equipment seen here.

Photos by Sam Thomas