UT’s Penumadu and Woracek Publish on New Research

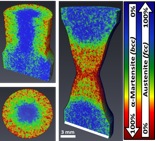

Dr. Dayakar Penumadu, Fred Peebles Professor and head of the Department of Civil and Environmental Engineering; PhD student Robin Woracek; and collaborating researchers at the Helmholtz Zentrum Berlin (HZB) in Germany have developed a novel method in which crystalline phase distributions can be visualized and quantified within the bulk of metallic samples.

This new method overcomes the limitations of existing techniques which are effective to study surfaces or small-size specimens, and also allows a 3-D in situ representation of the phase fractions within the sample volume under extreme environment (thermo-mechanical and acoustic).

Their research has just been published in the journal Advanced Materials. Their article is available for early view at here. It will be featured on the cover. This new characterization technique applicable for advanced and natural materials will have a major immediate impact in developing super-elastic and shape memory alloys which are having notable medical applications also.

The collaboration between UT’s Penumadu and Woracek and the Neutron Imaging group at HZB—Dr. Nikolay Kardjilov, Dr. I. Manke, and Dr. Andre Hilger—is focused on establishing new quantitative imaging methods by making use of diffraction contrast due to Bragg scattering.

Since the measurement method uses neutrons of selected wavelengths, the current work will also pave the way to implement such methods at Spallation Neutron Source at Oak Ridge National Laboratory.

For many engineering applications it is of major importance to characterize the bulk of materials spatially, instead of only probing selected locations. The new method provides exactly that capability and the HZB-UT team has demonstrated it using samples made from stainless steel that undergo a phase transformation after being subjected to tensile and torsional deformation.

Such steels are widely used as automotive and aerospace structural alloys, for major appliances, household items, and buildings. The new characterization method can be used to improve both material properties and manufacturing processes. However, the same method is naturally applicable to a wide range of natural and advanced materials.