UT Hosts, Wins Back-to-Back SEC Machining Competitions

The University of Tennessee, Knoxville, welcomed four teams of students from Southeastern Conference schools for the second annual SEC Machining Competition, held Nov. 8 and 9 at the Tennessee Manufacturing and Design Enterprise Building (TN-MADE) in Hardin Valley, and again the team from UT took top honors.

For Tony Schmitz, a professor in the Department of Mechanical, Aerospace, and Biomedical Engineering who came up with the idea for the event, being able to host it and emerge with a victory was a win-win for UT.

“Hosting this event for the second year in a row is a tremendous opportunity for the Machine Tool Research Center. While the intent is to foster a culture of cooperation and collaborative learning, it’s a nice addition to win two years in a row,” said Schmitz. “All these students have committed to advanced manufacturing education, and they demonstrated what they’ve learned today.”

While the competition takes center stage at the event, the overall concept is to attract university students to learn advanced manufacturing techniques, develop skills for the workforce of tomorrow, and fulfill the charge given to and the promise of land-grant universities.

“Advanced manufacturing is crucial to the U.S. economy and defense. We’re interested in helping to meet this need by restoring jobs that moved to other countries in the past decades,” said Schmitz. “Friendly competitions like this create a network of university students who will be tomorrow’s manufacturing leaders. We are building relationships between our institutions that will support and grow U.S. manufacturing.”

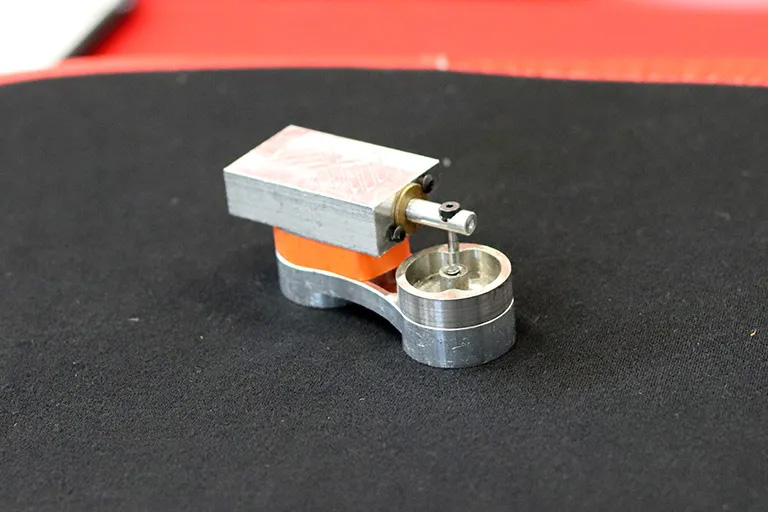

In addition to UT, participants included Mississippi State University, Texas A&M University, the University of Florida, and the University of Missouri. Teams each machined components for an oscillating piston air engine using a randomly assigned CNC machining center.

UT’s team consisted of graduate research assistant Dylan Pollard, from North Canton, Ohio, senior Mac Patrick, from Oak Ridge, and junior Olivia Teska, from Berkeley Heights, New Jersey.

Teska said competitions like this are important because bridging the gap between engineering and the manufacturing world would create a more efficient and cost-effective workplace that could have more products released in a shorter amount of time.

“I think this competition is important because it brings a sense of competition and inclusion to an industry that does not have a very large younger generation,” she said. “As someone who grew up with a family of machinists, I know firsthand that there aren’t many high schools, let alone colleges, that have machining teams and/or the facilities. I see this competition as a way to show other schools — colleges and high schools or even younger than that — that machining is still a very dominant industry that keeps changing as new and better technologies emerge.”

The event is a partnership between the U.S. Department of Defense Industrial Base Analysis and Sustainment program; Project MFG; America’s Cutting Edge; the Southeastern Advanced Machine Tools Network; the Oak Ridge National Laboratory Manufacturing Demonstration Facility; the UT-Oak Ridge Innovation Institute; the participating SEC universities; MSC Industrial Supply Co., which provided cutting tools; ZEISS, which provided part measurement; and the Gene Haas Foundation, which supports the Machine Tool Research Center where the event was held.

Schmitz added that he hopes to continue to expand the field to more SEC schools and eventually schools from other conferences, all of which will lead to a stronger future for the country.

Contact

David Goddard (865-974-8304, cgoddar5@utk.edu)

Photo Gallery