Industrial Engineering, BS

As companies adopt management philosophies of continuous productivity and quality improvement to survive in the increasingly competitive global market, the need for industrial engineers is growing on an international scale. We are cultivating the next generation of innovative thinkers through our comprehensive undergraduate program that prepares students for successful careers in the field of industrial and systems engineering.

Program overview

Our industrial engineering program prepares students for careers in a number of industries through honing problem-solving skills and expertise in their field, preparing students to meet today’s engineering needs. Through our undergraduate program, students will build on a strong foundation in engineering principles through a blend of rigorous course curriculum, hands-on research opportunities, and public service engagement.

As a student in our program, you’ll have access to undergraduate research, co-ops, and internships with ORNL and other industry partners to reinforce classroom learning, clarify career interests, and stimulate interest in graduate study. If you’re a self-starter with an aptitude for creative problem-solving and leadership, this program is for you.

Why Study Industrial Engineering?

Industrial engineering is a multidisciplinary and evolving field focusing on efficiency and sustainability, where engineers create real-world impacts in high earning jobs. Our undergraduate program prepares students for such a future, with endless possibilities for thinking outside the box, honing problem-solving skills, growing leadership and management potential, and creating strong industry connections.

Program at a Glance

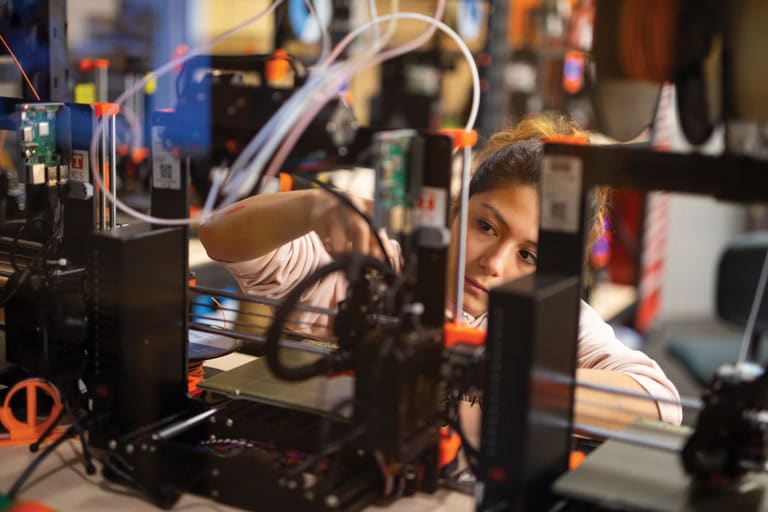

Committed to providing an exceptional modern industrial engineering education, our program stands out among other private and public institutions. Students study under 22 world renowned faculty in a 3:1 student to faculty ratio, providing a large-scale university experience in a small-scale context with better exposure for learning opportunities and professional growth. Research opportunities are available during the summer and throughout the year to reinforce classroom learning, clarify career interests and goals, and stimulate interest in graduate study. Students will work alongside faculty with access to cutting-edge technologies through our various labs and centers.

What can you do with a BS in Industrial Engineering after graduation?

While other types of engineers design things, industrial engineers design the systems that enable those things to work effectively. They design, install, improve, and control large, complex systems that include the integration of people, materials, machines, and facilities with wide-ranging applications including:

- Manufacturing

- Healthcare

- Service

- Transportation

- Energy

- Finance

Featured Courses

Below are some of the courses that students in our program can choose to take. For a list of all courses, visit the undergraduate catalog.

IE 201 Introduction to Industrial and Systems Engineering

This course introduces the incoming Industrial and Systems Engineering (ISE) students to the different aspects of the practice of industrial engineering including but not limited to supply chain logistics, healthcare, manufacturing, and service operations, etc.

IE 402 Production System Planning and Control

Theory and application of forecasting systems, including regression and time series models. Independent demand inventory models, including development of safety stock. All modules of Manufacturing Resource Planning (MRP) Systems. Master production scheduling, resource requirements planning, bill of material and inventory file structures, material requirements planning, capacity planning, shop floor and purchase order control. Overview of just-in-time inventory concepts and MRP’s role in manufacturing automation.

IE 444 Manufacturing Systems Modeling and Analysis

Introduces modern manufacturing through the lens of systems modeling and analysis. The main topics of this course will cover a broad range of concepts, including history of industrial evolution; holistic view of manufacturing from humans, materials, processes, machines, and systems; manufacturing operations management; system and data driven research paradigms; dynamic systems modeling and analytics methods; digital twin techniques; machine learning and artificial intelligence for manufacturing. Real-world and hands-on examples, including subtractive and additive manufacturing, green hydrogen production, manufacturing enterprise management, are used to illustrate and facilitate the adoption of systems modeling and analytics techniques in manufacturing.

IE 422 Industrial and Engineering Design II

Current real-world problems will be drawn from local production and service organizations and presented by personnel from these organizations. Senior industrial engineering student teams will solve these real-world problems under the guidance of their instructor using industrial engineering methodology. These problems emphasize problem definitions, analysis, and presentation with considerations for engineering standards and realistic economic, environmental, ethical, safety, social, political, and other pertinent constraints.

Complementary minors

Interested in pursuing a minor to expand your engineering expertise? See below for a list of options that would pair well with an industrial engineering degree.

Admissions and Aid

Choosing the right university to pursue an engineering degree is an important decision—and a significant investment. We want to make sure that you have the information you need to both apply and make attending UT affordable.

Ready to Join Us?

See yourself on Rocky Top? We’ve made it easier than ever to apply for admission. Learn more about our admission requirements and the steps to apply to be an Engineering Vol.