Chemical Engineering, BS

Chemical engineers are the ones behind the design, production, transformation, and implementation of processes used for chemicals and materials we utilize in our lives daily. From creating insulin to keep diabetics alive to creating the next viral skin care product, your journey in chemical engineering can start here.

Program overview

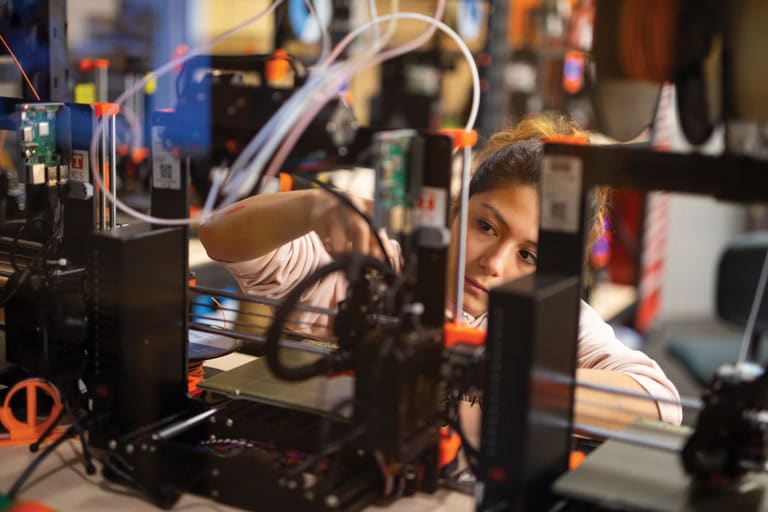

As part of our chemical engineering program, students will gain technical knowledge in chemical processes, thermodynamics, and materials science through hands-on experiences at the hands of our award-winning faculty. With access to state-of-the-art facilities, like the Eastman Unit Operations Laboratory, our chemical engineering students get to learn real-world practices in a safe, controlled environment, preparing them for their future career.

Biomolecular Concentration

Traditionally, the three main components of chemical engineering are chemistry, physics, and mathematics. Over the last 20 years, the role of biology has dramatically increased in this field. Biology provides more efficient, highly selective ways to increase complex molecules used in the chemical process industry, which is why we offer an optional biomolecular concentration for our chemical engineering degree.

Why Study Chemical Engineering?

Chemical engineers use their understanding of chemical and biological processes in combination with molecular information and discovery to develop new processes and products in various industries. Our BS in Chemical Engineering program provides students with education that gives them a foundation to advance human health and improve environmental conditions.

What is chemical engineering?

Chemical engineering is an interdisciplinary field that uses chemistry, math, physics, and biology to invent and optimize new technologies and products to improve quality of life. It includes designing new equipment; improving processes for producing chemicals, fuels, pharmaceuticals, and more; and altering the chemical, biochemical, or physical state of a substance.

What do chemical engineers do?

The world of chemical engineering is vast, providing students with a variety of paths they can take after graduation. Chemical engineers affect production in almost every aspect of manufacturing. Some of the most common tasks found in the discipline are:

- Designing and planning equipment layout

- Monitoring and optimizing production processes

- Ensuring compliance with environmental, health, and safety regulations

- Conducting research to improve processes

What can you do with a BS in Chemical Engineering after graduation?

From experiments in the lab to implementation of technology in production, chemical engineers are the force behind the processing of materials and chemicals we use daily. Many work in manufacturing plants, research labs, or production plants.

Chemical engineers are involved in a wide range of industries, including:

- Pharmaceuticals

- Healthcare

- Manufacturing

- Environmental health and safety

- Food processing

- Advanced materials

- Alternative fuels

Featured Courses

Chemical engineering graduates possess the knowledge base, intellectual skills, and professional commitment which prepare them for innovative technical leadership, graduate study, productive service to society, and continued professional growth through lifelong learning. Our curriculum provides a central core of required courses with the flexibility for students to prepare for graduate school or professional employment, and to concentrate in either chemical or biomolecular tracks. Check out some of the courses offered below.

CBE 201 Material and Energy Balances

In this course, students will learn about steady-state and transient material and energy balances in chemical and biomolecular systems

CBE 250 Application of Chemical and Biomolecular Engineering Thermodynamics

Since thermodynamics is an essential subject to learn for chemical engineering, students will take this course to understand the fundamental concepts related to applications of engineering thermodynamics, specifically in the chemical and biomolecular industries. Significant subjects taught in the course include processes and state changes of fluids and analysis of processes, such as power generation.

CBE 340 Mass Transfer and Separation Processes

In CBE 340, students will learn how to apply analytical, graphical, and computer methods to the design of stagewise separatory operations. The course also goes over differential operations and the application of analytical and computer methods to the design of diffusive processes.

CBE 360 Process Dynamics and Control

Students are introduced to process modeling and industrial control system design in CBE 360. They will use mathematical tools for characterizing the behavior of processes, and students will learn the theory and practice practical applications of operating and controlling these systems.

Complementary minors

Are you interested in expanding your education? Look at these minors that pair well with a chemical engineering, BS degree.

Admissions and Aid

Choosing the right university to pursue an engineering degree is an important decision—and a significant investment. We want to make sure that you have the information you need to both apply and make attending UT affordable.

Ready to Join Us?

See yourself on Rocky Top? We’ve made it easier than ever to apply for admission. Learn more about our admission requirements and the steps to apply to be an Engineering Vol.