Makers Club Helping Turn Student Ideas Into Reality

A recently formed club at UT has provided students with an outlet to bring their ideas to life via a mix of traditional and cutting-edge manufacturing methods.

The Makers Club began last semester with the goal of bringing together students and faculty interested in the makers movement, a group united by the idea of people learning and maintaining practical skills that were once common but are now in danger of being lost to machine automation—such as welding—and to developing skills in cutting-edge techniques such as 3D printing.

The Makers Club focus on turning ideas into reality is attracting students from various majors across campus.

“It started because of an idea we had in class,” said Chase Cumbelich, a junior from Ooltewah, Tennessee, majoring in electrical engineering, who helped found the club. “We kept hitting a wall while we were trying to develop something, and we realized our lack of contact and knowledge with other majors was really hampering us.

“We reached out across the college and got about 30 people interested, and the club just kind of snowballed from there.”

Now that club is changing the life of a classmate.

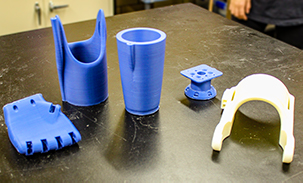

One of the first things the group was able to produce was a 3D-printed hand, developed with other engineering students.

At a group meeting, the question was raised whether anyone knew of someone who might be in need of such a hand.

Riley Toll, a freshman from Memphis in biomedical engineering, stood up and said, “Yeah . . . me.”

“I’d heard about the group and had a lot of interest,” said Toll. “Things like this are one of the reasons I was interested in engineering to begin with—to be able to help people and give back.

“Hopefully this brings some awareness to what can be accomplished through engineering.”

Chad Duty, associate professor of mechanical, aerospace, and biomedical engineering, introduced the idea of 3D-printed prosthetics to the Makers Club, stemming from an ongoing effort of a group called the Enable Community Foundation. The Enable group matches up patients across the world who are in need of prosthetic appendages with groups like the Makers Club that have access to 3D printers.

The two parties work together to get the prosthetic limb fitted to the specific size and needs of the patient, and it is delivered free of charge.

Duty pointed out that groups like Enable that bring people together for a common cause underscore the role of having a network of makers and the promise that such innovators hold.

“There are a lot of good things that can be accomplished when groups of people work together,” said Duty. “The sky is the limit.”